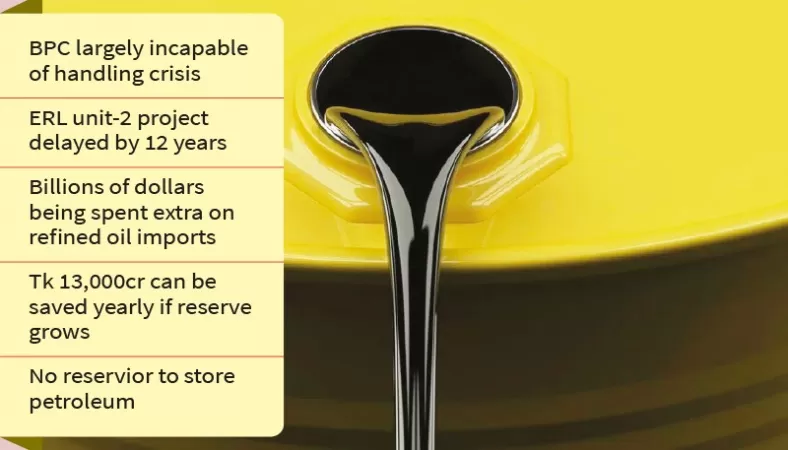

Protracted delay in establishing a fuel oil refinery, and lack of reservoir to store imported petroleum caused mainly by inertia of the Bangladesh Petroleum Corporation left the state agency in backwater in this trying time.

The current energy crisis crippling the country’s economic activities and everyday life could have been averted to a great extent if planned refinery installation undertaken above a decade ago had been set up in the port city in due time, experts have said.

As an obvious consequence, the government has been spending a lot of money in extra payments for importing refined liquid fuel, thanks to the BPC.

As the ERL unit-2 project remains unimplemented for long 12 years, BPC has to import refined oil to meet three-fourth of the domestic demand, causing the government to spend thousands of crores of taka in additional payments.

The project is supposed to refine around 30 lakh tonnes of crude per annum.

BPC faces trouble whenever fuel prices increase in the world market. It managed to overcome the previous crises, but the present one is posing major challenges.

In 2022, BPC will need more than twice as much to import refined oil as last year. But due to dollar shortages in Bangladesh, refined oil suppliers are reluctant to continue supply, BPC sources said.

BPC officials say such a big crisis would not have arisen if the ERL unit-2 project could have been implemented on time. A senior BPC official told The Business Post there were opportunities to increase reserve capacity, but that was not done. “Now the problem has worsened.”

The chairman of BPC, ABM Azad, could not be reached for comments on the matter.

12 years of frustration

According to BPC, the annual fuel consumption in Bangladesh is 60 lakh tonnes. Of this, 45 lakh tonnes are imported as refined oil while the rest comes as crude oil.

This crude oil is refined at BPC’s sister concern Eastern Refinery Limited (ERL) in Chattogram. It is the country’s only oil refinery established in 1968. As it expired in 1998, its refining capacity has decreased to 15 lakh tonnes.

In this situation, the government in 2010 decided to set up a new plant named ERL unit-2 with an annual refining capacity of three million tonnes. At that time, the project’s estimated cost was Tk 13,000 crore.

French company TechnipFMC built Eastern Refinery, and it was again selected as the contractor for unit-2. Besides, Engineers India was appointed as a consultant for the project in 2016.

The project cost has gone up at least 10 times since 2010. Now the estimated cost is around Tk 20,000 crore.

A senior BPC official told The Business Post various quarters of the government are hindering the project’s implementation to give advantage to private refineries. He said a former energy secretary, a major energy company, and some corrupt government officials had been opposing the project citing high costs of French technology. “They are actually trying to give the project to a Chinese company at half the rate.”

State Minister for Power, Energy and Mineral Resources Nasrul Hamid in September 2020 expressed extreme dissatisfaction with the project’s progress. Eastern Refinery’s then managing director Aktarul Haque was replaced by Mohammad Lokman in January last year due to the delay in the project.

TechnipFMC pulls out

Eastern Refinery officials said the company would be able to refine 45 lakh tonnes of oil annually once the second unit is commissioned, which would save about a billion dollars yearly.

An agreement was expected to be signed during Prime Minister Sheikh Hasina’s visit to France last year, but that did not happen. TechnipFMC recently informed Eastern Refinery that it would not take on the project.

The Eastern Refinery managing director told The Business Post on Friday the project had to go through many obstacles since the beginning.

“Besides, TechnipFMC has wasted a lot of our time. We will have a meeting with the Indian consultant next week. The project is expected to take off soon. Then there will be visible progress.”

Possibility to save $1 billion yearly

BPC’s finance department told The Business Post on Friday about $2.6 billion was spent on fuel imports last year, including $2.2 billion on refined oil.

Due to the increase in fuel prices in the world market this year, per barrel of crude oil had to be bought at $112 and refined oil at $140 on July 20. Refined oil prices went up to $180 a few days ago.

BPC says refined oil imports spending will reach $5.5 billion this year while it will be $2 billion for crude oil.

Manilal Das, general manager of BPC, said Eastern Refinery currently spends Tk 190 on refining each barrel of oil.

“The cost is Tk 6 less than imported refined oil per litre. This cost will reduce further if the second unit goes into operation. We will then be able to save $1 billion annually.”

According to BPC, Bangladesh imports refined oil from several companies in China, Malaysia, and Indonesia. But these countries do not produce oil. They import oil from fuel exporting countries, refine it, and then export it to Bangladesh.

Alternative steps can increase savings

China can store fuel for a year while it is six months for India and Pakistan. But Bangladesh can store fuel for only 42 days, which has now come down to 25 days due to the ongoing energy crisis.

Experts believe BPC cannot take advantage of drops in global oil prices due to insufficient reserves. But it has several options. For example, it can rent tankers from private companies as well as public and private oil-based power plants.

This way, it is possible to store at least 25 lakh tonnes of oil. This will add at least another eight months of reserve capacity.

In 2020, global oil prices fell to minus $40 per barrel due to the coronavirus pandemic. At that time, energy expert Professor M Shamsul Alam said it would have been possible to save at least Tk 13,000 crore if oil could be bought and stored using the alternative techniques.