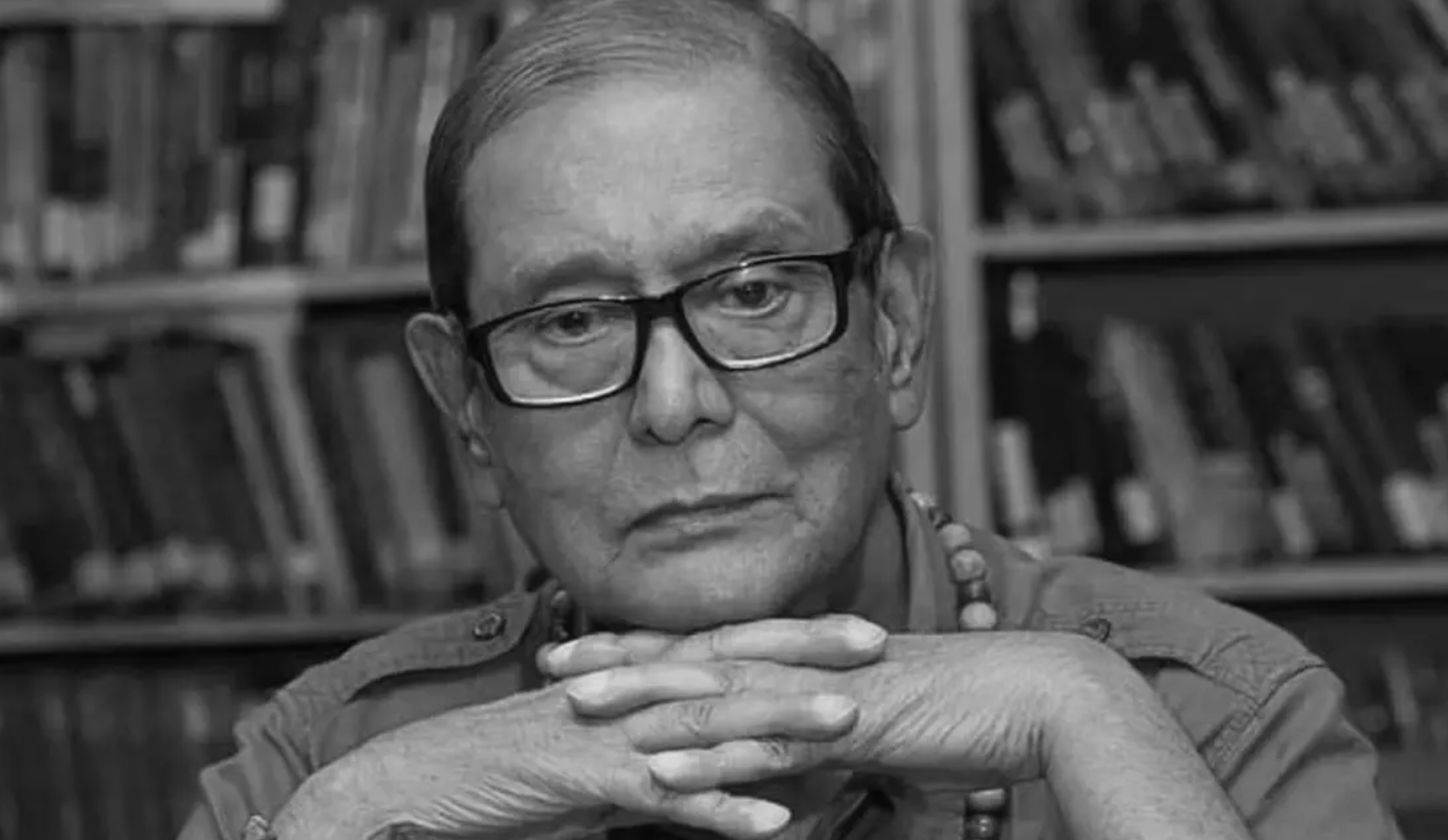

To expand the RMG sector to a more than $50-billion industry, Bangladesh needs to secure uninterrupted access to electricity and gas for the factories, among many other things. Photo: Mumit M

To expand the RMG sector to a more than $50-billion industry, Bangladesh needs to secure uninterrupted access to electricity and gas for the factories, among many other things. Photo: Mumit M

The Bangladesh RMG sector is experiencing a sharp rise in orders and exports due to increased global demand and lockdown in certain countries such as Vietnam and Indonesia, which supply garments to the same global retail destinations.

Bangladesh's export has had steady growth since January 2021 with export earnings in FY21 increasing by $5.08 billion, compared to that of FY20. Moreover, the volume of export has been growing more rapidly since May of this year.

The number of orders placed in Bangladesh for autumn/winter is high, with even higher confirmed orders for spring-summer 2021-22. Many of the factories are booked to full capacity till March 2022. If export growth continues, export earnings will reach or exceed the pre-pandemic level in 2022. But this growth comes with tremendous challenges.

Although the demand for RMG grew, the average RMG unit price did not increase as one would expect with the rising demand. This is due to excess capacity for generic products available from the Bangladesh RMG market and a lack of product diversification. So, too many vendors are competing for the same orders in the woven and basic knitwear categories.

In that regard, the BGMEA can also play a role in increasing capacity in each of the categories such as denim, casual shirts, chino pants, cargo pants, basic t-shirts, polo shirts, etc. and make proper capacity suggestions on categories among its members. This way, the unhealthy price war could be resolved.

The challenges, limitations and pressures

With increased demand from the RMG industry, the global cotton stocks fell to a three-year low.

According to a recent report by the World Bank, the average price for raw cotton in the first quarter of 2021 was $1.64 per kg, which is 3 percent higher than the average price in 2020.

In the fourth quarter of 2021, the prices are projected to rise to $1.72 per kg or higher. Also, the global fashion industry has banned the use of cotton produced in China's Xinjiang province due to human rights concerns, which caused a steeper rise in price.

Although the retail clothing price increase is an encouraging sign, much of that increase is being gobbled up by the increased raw material prices and the sharp increase in transportation and shipping costs.

Rising ocean freight rates, limited carrying space in the ships as well as the lack of availability of containers have remained a major challenge since February 2021. Drewry's composite World Container index increased sharply to $10,083.84 per 40-foot container for the week that ended on 9 September.

In fact, the average composite index is now 309 percent higher than that of a year ago. This is an astronomical rise, indicating a sharp rise in supply chain costs worldwide.

Since the retailers and buyers are trying to maintain or increase their profit margin after Covid-19 with a vibrant retail environment, some of the pressures are being passed down to the manufacturer. Thus, even though the demand and orders have increased, manufacturers are still facing tremendous financial and other challenges.

On top of the global supply chain challenges, local export-related infrastructure also poses a huge challenge. In today's retail environment where demand and fashion are changing fast, the demand for samples and small marketing promotional shipments, as well as shipment by air, is on the rise.

Unfortunately, the Bangladesh RMG manufacturers are faced with extremely poor and inadequate infrastructure for air cargo shipment. There are only two security scanners that remain broken most of the time.

Hence sometimes manufacturers have to ship the air cargo or packages via Kolkata, India, where the packages can be scanned and sent. Why the second largest garments manufacturing nation in the world would face such a shipping issue remains a mystery but the manufacturers' woes remain endless.

Yet the perseverance of the entrepreneurs in the RMG sector remains high as they work hard to take the sector to new heights no matter what the challenges are. Still, the government and aviation authorities should fix this very simple but very important issue as quickly as possible.

Similarly, access to electricity and gas remains a major issue for RMG manufacturers. Although by the book Bangladesh is supposed to have no electricity shortage, the reality on the ground is different.