Even though it has taken 19 years to implement the project that was initially scheduled to be completed in two years and the project cost has gone up by six times in the meantime

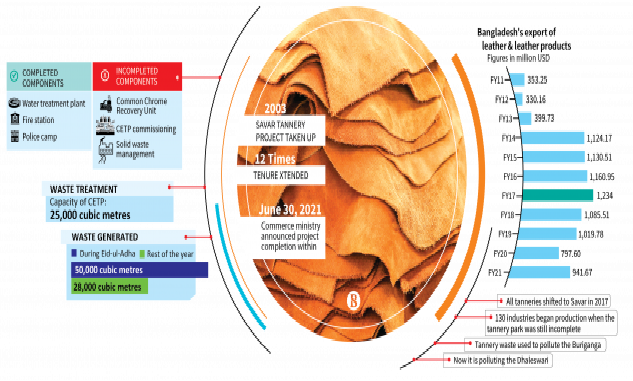

The Ministry of Industries on 30 June this year announced the completion of the Tannery Industrial Estate project at Hemayetpur in Savar – aimed at attracting foreign investment and increasing exports by setting up a compliant modern environment-friendly leather industrial park.

Even though it has taken 19 years to implement the project that was initially scheduled to be completed in two years and the project cost has gone up by six times in the meantime, tannery owners think the leather industrial city is "incomplete" and "environmentally unfriendly".

None of the objectives behind the project, that include attracting foreign investment in the export-oriented sector that is dependent on domestic raw materials and increasing export earnings, is being fulfilled. In fact, export earnings in the sector have been declining fast since the tanneries were shifted from Hazaribagh to Savar four years ago.

Before it was declared complete, the two-year project was the oldest project in Bangladesh's Annual Development Programme (ADP).

Although the deadline of the project, taken up in 2003, was extended 12 times and the cost was increased from Tk175 crore to Tk1,015 crore, construction of the common chrome recovery unit to stop environmental pollution has not been completed, said the Bangladesh Tanners Association.

There is also no provision for resource generation through solid waste management, the association added.

Under the project, a central influencer treatment plant (CETP) was supposed to be set up within two years, but it took more than seven years to complete its construction due to dilly-dallies by the Chinese contractor concerned and the failure of the industries ministry.

However, the refining capacity of that CETP is only half of the waste generated by the tanneries during the peak season. Therefore, the waste is being discarded before it is fully treated in the CETP.

And since no measures have been taken to treat the solid wastes generated by the tanneries, the once clean and clear Dhaleshwari river water is now getting polluted – in a similar manner the water of the River Buriganga was polluted by tanneries at Hazaribagh.

And this is happening in a situation when compliance is the main challenge for tannery and leather goods manufacturers.

Although it was important to ensure compliance with the ESQ (environment, social and quality), ISO and other national and international standards, it was not possible.

On the other hand, in spite of their reported failure to execute the project, the Ministry of Industries has come a long way in taking up a new two-year project to build another leather industrial park of the same size next to the existing one. The detailed project proposal (DPP) has already been sent to the Planning Commission.

The government declared the 2016-17 fiscal as the "Leather Year". But, interestingly, the downturn in the leather industry began from that time.

To develop the sector, a taskforce was supposed to be formed under the leadership of the industries minister and hold meetings regularly, but that did not happen.

As a result, notwithstanding the availability of high quality leather, the country's leather and leather goods exports to the international market have been declining for seven years due to a lack of environmental compliance in processing and production.

Buyers – based in the United States and Europe – are moving away from Bangladesh in the absence of Labour Working Group (LWG) certification.

After the relocation of the tanneries from Hazarbagh in 2017, the leather and leather goods exports started to decrease further. In the following year, the leather sector lost its second place in terms of sector-wise to export earners in the country and came down to the third position.

The project implementing agency, the Bangladesh Small and Cottage Industries Corporation (BSCIC), now says the issues needed to be taken care of for building a full-fledged leather industrial city were not included in the project. The Chinese firm was hired to arrange for solid waste treatment but it did not do so, according to the BSCIC.

While on a visit to the leather industrial city recently, The Business Standard found that work on the infrastructure development was over. Works on setting up a fire station, police outpost and water treatment plant were complete. The CETP with a daily refining capacity of 25,000 cubic metres also was operational.

But, during the processing of a massive volume of rawhide following Eid-ul-Azha, as high as 50,000 cubic metres of waste are generated per day. During the rest of the year, the tanneries produce 28,000 cubic metres of waste each day.

Because the amount of waste being produced by the tanneries is much higher, it is dumped in the River Dhaleshwari before it is fully treated.

The solid waste management is also in dire straits. Tannery solid waste is being dumped in open spaces on the bank of the Dhaleshwari in the western part of the leather industrial city, which is polluting the river as well as the environment.

According to local people, alongside contaminating the Dhaleswari water, the waste being dumped in open spaces is polluting the air of the surrounding areas.

Dr Ahsan H Mansur, executive director of the Policy Research Institute (PRI), said the tannery estate project in Savar is the best example of project mismanagement in the country.

"The BSCIC is not eligible for executing such a project. They can implement poultry rearing projects. A competent organisation like the EPZ Authority must have been given this task."

Mentioning that the leather industry is a very environmentally sensitive sector, the noted economist said based on what the BSIC did with the CETP, the project should have been taken away from them and handed over to someone else ten years ago. But, the government did not do so. If any new project is planned through them, it will also fail completely."

Meanwhile, the Bangladesh Tanners Association, an association of tannery owners, has written to the industries and commerce ministries to extend the project for another two years, terming the industrial city as "incomplete" and "environmentally unfriendly".

The association's President Shaheen Ahmed told TBS, "We have requested for extension to the project till June 2023 due to incomplete construction of the common chrome recovery unit, CETP commissioning, and a lack of resource generation through solid waste management."

Tannery Industrial Estate's Project Director Jitendra Nath Pal told TBS the project was delayed for various reasons in the past. "But, now all the work of the project has been completed including the installation of a CETP. A new project is being undertaken in this industrial city by incorporating other necessary issues including installation of solid waste management."

According to people concerned, the journey of the leather sector in this country as a business started in the forties of the last century. In 1940, businessman Ranada Prasad Saha (RP Saha) established the first tannery near Narayanganj.

About a decade later, the then government set up a tannery in Hazaribagh, Dhaka.

After the country's independence in 1971, the sector played an important role in earning foreign exchange from wet blue exports.

The post-1990s period saw a diversification of export goods through the production of crushed and finished leather, shoes, bags and other leather goods.

During that period, the leather and leather products of Bangladesh became known abroad and the leather industry emerged as the second largest export earning sector, outshining the jute sector.

In 2013-14, the country earned $1.26 billion by exporting leather and leather products. In the last financial year, the sector fetched $941 million.

An example of gross mismanagement

In order to prevent environmental pollution, the BSCIC under the Ministry of Industries undertook a project in 2003 to set up a compliant leather industrial city in Savar by constructing all modern facilities including waste management such as STP, CETP, dumping yard in a scientific manner.

Initially, the reluctance of tannery owners to leave Hazaribagh delayed the implementation of the project.

Highlighting the aims and objectives of the project, the project document said a modern industrial city including a CETP would be constructed in Savar where all tanneries would be relocated from Hazaribagh and other parts of the country and would be provided with necessary support in eco-friendly production.

The leather industry would be developed and modernised by providing other facilities including infrastructural facilities to the leather industry entrepreneurs, the document further said, adding a conducive environment would be created to increase production and exports by attracting foreign investment in this sector.

As a result, employment would be created here and the contribution of the leather industry to the national economy would increase, it further read.

It was initially said that the tanneries themselves would set up ETPs for industrial waste management, but they were not doing that. After much negotiation, the Ministry of Industries revised the project in 2010 with a decision to set up a CETP under the project. Then the project cost was increased to Tk545 crore.

A Chinese company got some technical work including construction of a CETP and dumping yard. In March 2012, the company was given a 24-month work order. To make the CETP more up-to-date, the total project cost was set at Tk1078.71 crore by adding a sewage treatment plant, sewage power generation system and solid waste management system in the project in the following year. The cost also included compensation of Tk250 crore to tannery owners.

BUET's BRTC was appointed to supervise and monitor the CETP construction work. In the fourth revision to the project, the estimated cost was increased to Tk1,015.56 crore, excluding the SPGS component, and the deadline was extended till June 2021.

But the Chinese contractor company could not complete the work on time. The company continued to increase the contract time on various excuses. The project implementing authorities also fell hostage to the company.

In the meantime, the Ministry of Industries repeatedly set deadlines for the relocation of tanneries without ensuring any facilities in the industrial city. The factories were relocated in April 2017 after the High Court ordered the authorities to disconnect the gas, water and electricity connections of the factories in Hazaribagh.

Before the completion of the various components of the CETP, 130 industries started their production.

Earlier, waste and polluted chemicals from Hazaribagh used to get mixed with the water of the River Buriganga. Now the pollution from the tannery estate in Savar is being mixed with the water of the River Dhaleshwari.

Meanwhile, the Department of Environment has started imposing heavy fines on the tannery estate authorities. Eventually, the CETP was installed, but environmental pollution continues due to its low capacity.

Land lease deed not yet complete

The tanneries shifted from Hazaribagh have got their own plots in Savar but are yet to pay the prices of the land. Only 4-5 companies have paid the full plot price and completed the lease deed thus far. The others paid only 1 or 2 installments, as a result of which they could not yet make lease deeds.

The BSCIC had given time till the end of the project period to pay the land price free of interest. Now that the project is over, the tannery owners will have to pay interest along with the price of the land.

Many entrepreneurs in this sector have already been defaulters by different banks. That is why they could not take out fresh loans. They are not able to offer their plots in the industrial estate as collateral to banks since they do not have any deed against the lease.

Tannery owners say they have to invest huge amounts of money in the construction of factory buildings, import of new machinery, transfer of old machinery etc in the project area. Many entrepreneurs have fallen into financial crisis due to long-term closure of factories, paying workers' wages despite factory closures, and payment of installments of loans.

Meanwhile, the abandoned land in Hazaribagh has been declared a "red zone" by the Rajdhani Unnayon Ktripakkha or Rajuk. That is why tannery owners are not able to sell their land or establishments or use them for any alternative purpose.

Neither the BSCIC nor the BTA could say how much the tannery owners had paid to the government against the lease of plots in the industrial city.

BTA President Shahin Ahmed traders had suffered losses during the transfer of the tanneries. "Traders have also suffered because of Covid-19. Again, there is ambiguity in the case of land deeds. All in all, the money is not being paid by the tannery owners."