The country’s yarn-producing spinning mills, which saw a drastic fall in business at the beginning of the global Covid-19 outbreak, is now reviving amid the second wave of the pandemic as worldwide staying home practice increased the demand for apparel products, particularly knitwear items.

Industry insiders said they are now receiving an increased number of orders from their buyers – local textile mills.

“We all businesspeople have incurred more than Tk 100 crore losses in the first phase of lockdown last year,” said Muhammad Ali Khokon, owner of Metro Spinning mill.

Currently, the yarn manufacturing sector is gradually reviving the business despite the second wave of the pandemic, Khokon, also president of the Bangladesh Textile Mills Association (BTMA), told the Business Insider Bangladesh.

“Already our sales have increased significantly. This time, we have a huge order at hand scheduled to be delivered by July this year,” he said, expressing a hope that the flow of orders would continue till the end of the year.

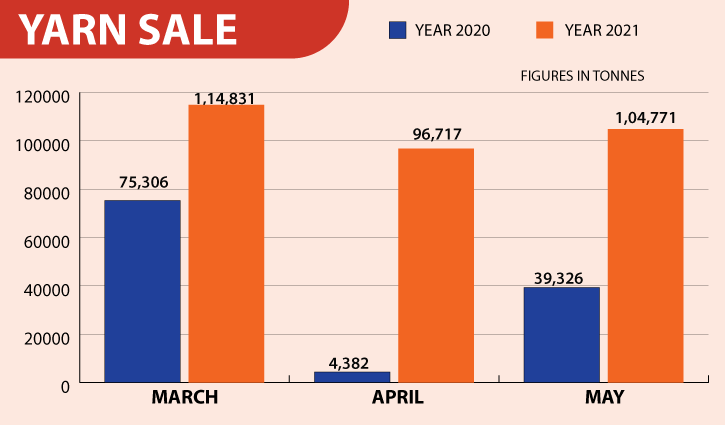

According to the BTMA, the country produced 39,326 tonnes of yarn worth Tk 967 crore in May 2020. It increased to 104,771 tonnes worth Tk 4,041 crore last month (May 2021), up by 318% year-on year.

The millers said they are now doing good business.

Usually, spinning mills collecting or importing fibres, cotton and other raw materials produce yarn and sell it to local fabric-makers – textile mills. Hardly, they go for direct exports.

Some textile mills produce the yarn at their own facilities. The yarn made fabric and finished-garment products finally being exported to different countries. In contrast, many readymade garment industries also import fabrics.

Sector insiders said the local yarn industry’s growth and fall depend on the apparel exports situation.

According to the Export Promotion Bureau (EPB), the readymade garments exports increased by 11.1% to $28.56 billion in the July-May period of FY2020-21.

Among the items, comfortable knitwear garments saw the highest 20.55% year-on-year growth, thanks to the western countries’ extra precautionary measures against Covid-19, like avoiding going outside, staying home, and working from home.

The rise in apparel exports ultimately favoured the local yarn manufacturing industry.

They said since August last year, sales of yarn have been on the rise.

“Though the second wave of the Covid-19 started in the meantime, we did not face any fall in business. The sector is getting better day by day,” said Fazlur Rahman, managing director of Ishraq Spinning Mill.

“Now we are recovering from the previously incurred losses,” Rahman said.

Md Badsha Mia, managing director of Kamal Yarn, said the business fell into a survival crisis last year.

“I have sold yarn at less than production costs and incurred huge losses,” he said, adding that the situation was different now.

“In the last five months, our stocks ran out. We are now tiringly supplying products as per buyers’ demand,” Mia said.

However, the yarn makers are concerned about the cotton price hike in the global market, as the increase in the raw material prices would cut their profit margin.

The prices of cotton went up by 10% amid the pandemic.